+86 180 0293 5268

+86 180 0293 5268

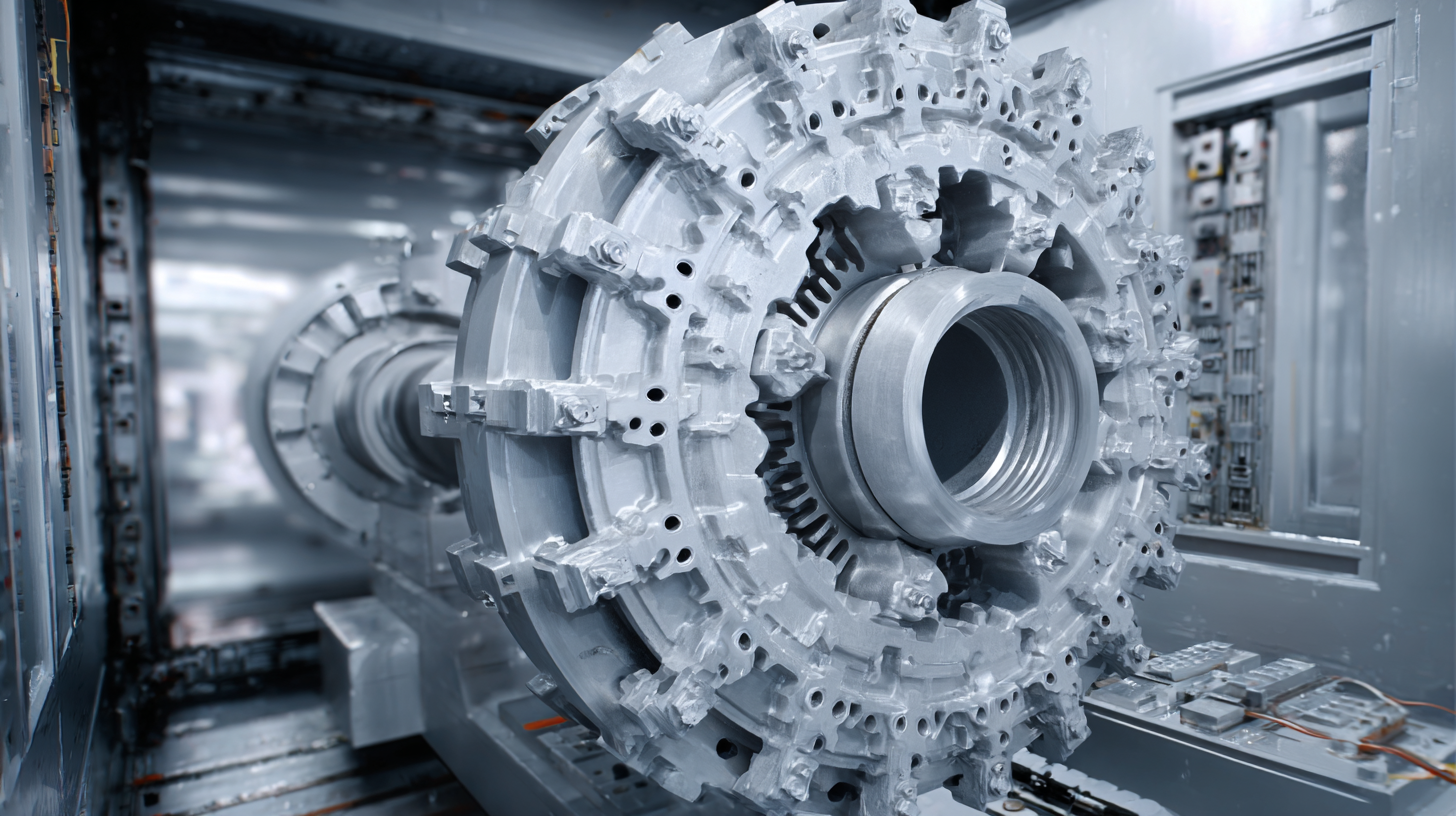

In the rapidly evolving landscape of manufacturing, High Tech Investment Casting stands out as a revolutionary approach that merges precision with innovation, providing unparalleled quality and efficiency. Originating from China's top-tier factories, this cutting-edge technique has garnered global trust for its ability to create complex geometries with remarkable accuracy and minimal waste. As industries strive for excellence in their production processes, embracing High Tech Investment Casting not only enhances product reliability but also drives sustainability efforts, addressing the growing demand for environmentally responsible manufacturing solutions. This blog will explore the innovative strategies and advancements in High Tech Investment Casting that are shaping the future of investment casting techniques, highlighting their significance in fostering global competitiveness and economic growth.

Advanced high tech investment casting techniques are revolutionizing the manufacturing industry by offering numerous benefits that enhance efficiency and product quality. These methods utilize state-of-the-art technology to produce complex geometries with exceptional precision, allowing manufacturers to create intricate designs that were previously impossible. The improved dimensional accuracy reduces the need for secondary machining processes, ultimately saving time and resources.

Tip: To maximize the benefits of high tech investment casting, manufacturers should consider investing in advanced software that aids in design optimization. This can lead to more efficient use of materials and energy, contributing to sustainable manufacturing practices.

Moreover, these techniques enable the production of lightweight yet robust components, which is particularly advantageous in industries such as aerospace and automotive. The ability to cast high-strength alloys decreases overall weight without compromising performance, leading to enhanced energy efficiency and lower operational costs.

Tip: Collaborating with experts in material science can further increase the effectiveness of investment casting. By choosing the right materials tailored to specific applications, businesses can improve their product lines and ensure greater customer satisfaction.

In today’s competitive manufacturing landscape, achieving cost efficiency is paramount, and innovative casting techniques play a crucial role in reducing production expenses. Modern investment casting methods, such as 3D printing and automated molding, streamline the casting process and lower material waste. By integrating technology, manufacturers can create precise and complex designs that not only enhance product quality but also save on raw materials. This approach allows companies to minimize inventory costs and reduce the need for extensive post-processing.

In today’s competitive manufacturing landscape, achieving cost efficiency is paramount, and innovative casting techniques play a crucial role in reducing production expenses. Modern investment casting methods, such as 3D printing and automated molding, streamline the casting process and lower material waste. By integrating technology, manufacturers can create precise and complex designs that not only enhance product quality but also save on raw materials. This approach allows companies to minimize inventory costs and reduce the need for extensive post-processing.

Furthermore, adopting eco-friendly and advanced materials can significantly decrease production costs. Innovations such as ceramic molds, which allow for higher temperature tolerances and improved durability, lead to fewer defects and reworks. As production processes become more efficient, companies can also benefit from shorter lead times, enabling them to respond quickly to market demands while maintaining high standards of quality. By investing in these advanced techniques, businesses are not only optimizing their costs but are also positioning themselves for sustainable growth in a rapidly evolving industry.

The advancement of high-tech investment casting techniques is revolutionizing the manufacturing landscape, significantly enhancing product quality through improved precision and durability. Modern casting methods, such as 3D printing and computer-aided design (CAD), play a pivotal role in creating intricate geometries that were previously unattainable. These innovations not only reduce waste but also ensure that the components produced meet stringent specifications, ultimately leading to better-performing products.

Tips: When evaluating casting techniques, look for providers who utilize state-of-the-art technology and maintain rigorous quality control standards. Moreover, consider the benefits of prototyping with 3D printing, which can drastically cut down lead times and allow for rapid adjustments in design based on real-world testing.

Implementing high-tech methods also enhances durability. By using advanced materials and refined casting techniques, manufacturers can produce components that withstand extreme conditions, thereby extending the lifecycle of the products. This not only benefits end-users through lower maintenance costs but also positions companies as leaders in sustainability.

Tips: Prioritize suppliers who specialize in high-performance alloys and have a proven track record in creating durable castings. It's essential to collaborate closely with engineers to ensure that all design and material choices align with the intended use of the final product, maximizing durability and minimizing potential failures.

The high tech investment casting industry is evolving rapidly, with sustainability becoming a key focus. Recent reports indicate that eco-friendly practices in manufacturing can reduce greenhouse gas emissions by up to 30%, significantly impacting the industry's carbon footprint.

Leading companies are innovating by adopting sustainable materials and refining their processes to minimize waste. For instance, the use of water-soluble binders instead of traditional petrochemical-based materials not only enhances mold quality but also aligns with eco-conscious manufacturing practices.

Moreover, the integration of renewable energy sources in factories is on the rise. A study by the Sustainable Investment Casting Alliance suggests that manufacturers implementing solar or wind energy can cut energy costs by nearly 40% while simultaneously promoting a greener manufacturing environment. These advancements not only meet consumer demands for sustainable products but also enhance operational efficiency.

As the industry continues to embrace sustainability trends, the focus on eco-friendly practices in high tech investment casting will likely drive further innovation, positioning companies for success in an increasingly eco-aware market.

The investment casting industry is experiencing significant growth, driven by advancements in technology and a strong emphasis on sustainability. As companies strive to meet eco-friendly standards, innovative solutions in high-tech investment casting techniques emerge, allowing for more efficient production processes that minimize waste and reduce carbon footprints. These technological improvements not only enhance the quality and precision of castings but also align with the growing market demand for sustainable manufacturing practices.

Looking ahead to 2025, the landscape of the metal casting industry is set for transformation. The introduction of new techniques and materials, along with the expansion of initiatives like the Belt and Road Initiative, presents both challenges and opportunities. Manufacturers must adapt to these changing dynamics, focusing on modernization and efficiency to remain competitive. With the global push for green technologies, the investment casting sector is uniquely positioned to leverage this trend, ensuring its continual advancement and relevance in a rapidly evolving market.