+86 180 0293 5268

+86 180 0293 5268

In the modern manufacturing landscape, precision and efficiency are paramount, which is why CNC (Computer Numerical Control) machined parts have gained significant prominence. According to a report by Markets and Markets, the global CNC machining market is projected to reach $100 billion by 2025, reflecting a compound annual growth rate (CAGR) of 6.2%. CNC machined parts are integral to various industries, including aerospace, automotive, and medical devices, due to their ability to produce complex geometries with high accuracy and repeatability.

As industry expert Dr. Emily Chen states, "CNC machined parts are the backbone of modern manufacturing; they enable companies to innovate and maintain competitive advantage." The importance of these components cannot be overstated, as they not only enhance the manufacturing process but also contribute to the overall quality and performance of the end products. The evolution of CNC machining technology continues to drive improvements in productivity and efficiency, ensuring that manufacturers can meet the increasing demands of the global market while adhering to stringent quality standards.

CNC machined parts are components created through a process called Computer Numerical Control (CNC) machining, which utilizes computer programs to control machine tools. This method allows for the precise cutting, shaping, and finishing of materials, such as metal, plastic, and wood, to create parts with exact specifications. The defining characteristic of CNC machined parts is their high level of accuracy and repeatability, which is essential in manufacturing applications where tight tolerances and consistent quality are paramount.

One of the primary attributes of CNC machined parts is their ability to be tailored to specific design requirements. The machining process can accommodate complex geometries and intricate designs that may be challenging or impossible to achieve through traditional machining methods. Additionally, CNC machining enables the rapid production of parts, which is vital in industries like aerospace, automotive, and electronics, where time-to-market can significantly impact competitiveness. The versatility, precision, and efficiency of CNC machined parts play a crucial role in modern manufacturing, making them indispensable in the production of high-quality and reliable components.

The CNC machining process is a critical innovation in modern manufacturing, enabling the precise production of complex parts from various materials, including metals, plastics, and composites. This automated technique relies on computer numerical control (CNC) systems to operate machinery with minimal human intervention, allowing for high accuracy and repeatability. According to a report by MarketsandMarkets, the global CNC machining market is expected to reach $117.3 billion by 2025, highlighting its significant role in various industries, from aerospace to automotive.

The process begins by converting a computer-aided design (CAD) drawing into a CNC program that dictates the machine's movements. This is accomplished through a series of steps that include setup, tool selection, and program execution. During execution, the machine follows the CNC program with utmost precision, utilizing various tools such as mills, lathes, and routers to cut, shape, and finish the material as required. A study from the National Institute of Standards and Technology (NIST) shows that CNC machining can reduce production time by up to 50%, while also minimizing waste and improving product quality. This efficiency not only drives cost savings but also enables manufacturers to meet the growing demands of customers with greater speed and accuracy.

CNC machined parts play a crucial role across a multitude of industries due to their precision and versatility. In the aerospace sector, for instance, these components are integral to the production of aircraft parts, such as brackets and housings, which require extremely tight tolerances to ensure safety and performance. The use of CNC machining allows for complex geometries and lightweight designs, which are fundamental in improving fuel efficiency and overall aircraft capability.

In the automotive industry, CNC machined parts are essential for both production and aftermarket modifications. Components like engine blocks, transmission cases, and suspension parts benefit from the accuracy of CNC machining, leading to improved performance and durability. Similarly, in the medical field, custom CNC machined components are produced for devices and instruments that demand high precision, such as surgical tools and implants, where even slight deviations can have significant consequences. Overall, the application of CNC machined parts enhances manufacturing efficiency, quality, and innovation across various sectors.

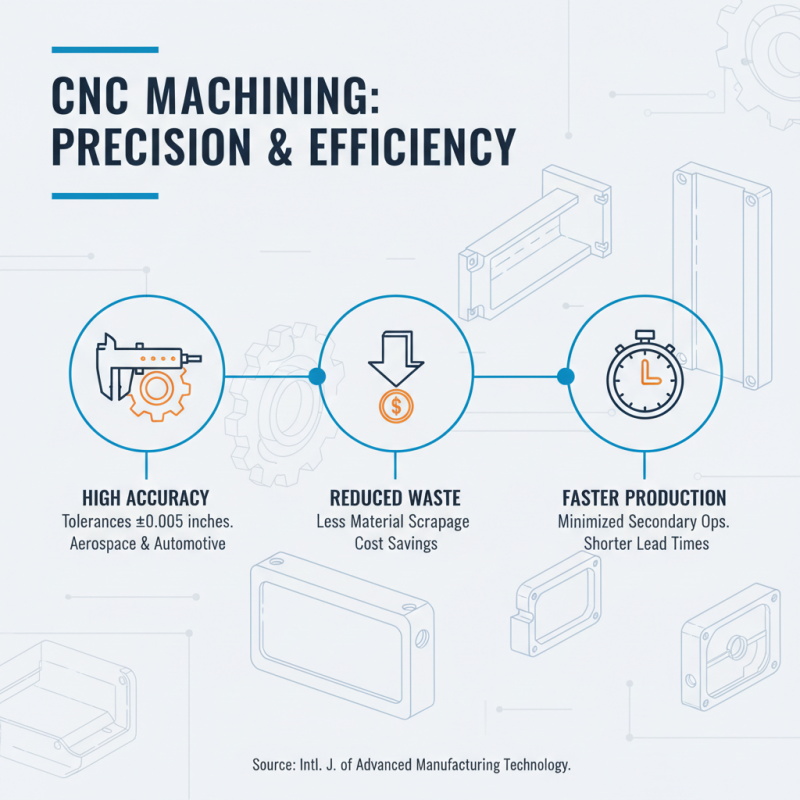

CNC machined parts are integral to modern manufacturing processes, offering a range of benefits that enhance efficiency and precision. One of the most significant advantages is the high level of accuracy they provide. According to a report by the International Journal of Advanced Manufacturing Technology, businesses leveraging CNC machining can achieve tolerances as tight as ±0.005 inches, which is crucial for industries such as aerospace and automotive where precision is non-negotiable. This level of accuracy minimizes material waste and reduces the need for secondary operations, ultimately leading to cost savings and shorter production times.

Moreover, CNC machining supports complex geometric designs that are difficult or impossible to achieve with traditional manufacturing methods. The advanced capabilities of CNC machines allow manufacturers to produce intricate parts that enhance the functionality and aesthetics of products. A study published by the Manufacturing Engineering Society reveals that companies utilizing CNC machining reported a 30% increase in production efficiency due to the ability to automate processes and scale up production without compromising quality. This adaptability is essential in a competitive market, enabling manufacturers to respond quickly to changing customer demands and reduce lead times effectively.

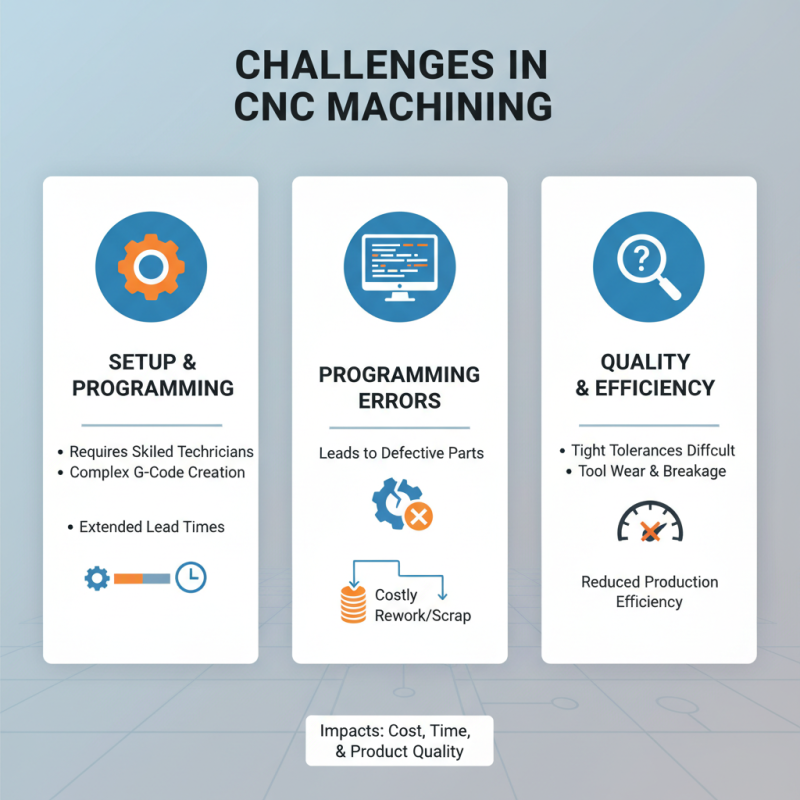

CNC machining, while a cornerstone of modern manufacturing, comes with its own set of challenges and limitations that can influence production efficiency and product quality. One significant challenge is the initial setup and programming of CNC machines, which often requires skilled technicians. The complexity of creating precise programming codes that control the machining process can lead to extended lead times and increased costs if not managed carefully. Additionally, errors in programming can result in defective parts, necessitating costly rework or scrap.

Another limitation lies in the material constraints presented by CNC machining. Not all materials can be easily machined due to their physical properties. For instance, harder materials may lead to faster tool wear, which affects both the machine's performance and the budget. Moreover, the geometrical limitations imposed by the machining process itself may restrict the design possibilities. Intricate designs or features requiring very tight tolerances can pose significant challenges, often requiring specialized tools or techniques that further complicate the manufacturing process.